Adhesive glue products are seen everywhere in modern life. We use them in households and also in schools and work places. We need them as a matter of fact. Many of them are filled in aluminum glue tubes.

As a consumer, we care about the quality of adhesive glue even if we barely know what these adhesives are made of. When an adhesive product does not work as well as we have expected, we tend to blame the adhesive itself. What we are not aware of is that, however, the problem might have something to do with the packaging material and the packaging process.

For those who work to develop and design adhesive products, it is not only the adhesive itself that matters, the packaging material and the packaging procedure are also essential. While we are not to know everything about them, there are a few points to address if we would like to come up with a good quality adhesive product.

Aluminum glue tubes are used to hold adhesive glue. It is expected that unopened tubes are air-tight so that the adhesive will not dry out or turn bad in the tubes. Also, it is expected that the adhesive does not react chemically to aluminum. Adhesives that are slight corrosive or sensitive to air/moisture need special pre-treated tubes to ensure air-tightness. There are three factors that affect air-tightness.

For sensitive and/or corrosive adhesive, internal lacquer is highly recommended.

Internal lacquering involves spraying the inner wall of aluminum tube with a layer of epoxy-phenolic resin. This special resin is resistant to chemicals such as acid, alkali and solvent. It forms protection so that the adhesive will not be in contact with chemicals from outer environment as well as with the aluminum wall.

For adhesive sensitive to air and moisture, latex lining is recommended.

Near the open end of the tube, the inner wall is to be lined with a circle/band of latex. This latex lining will enhance the air-tightness as the tube end is folded and crimped after filling. It prevents moisture and contaminants from penetrating into the tube.

Ways of folding and crimping also matter.

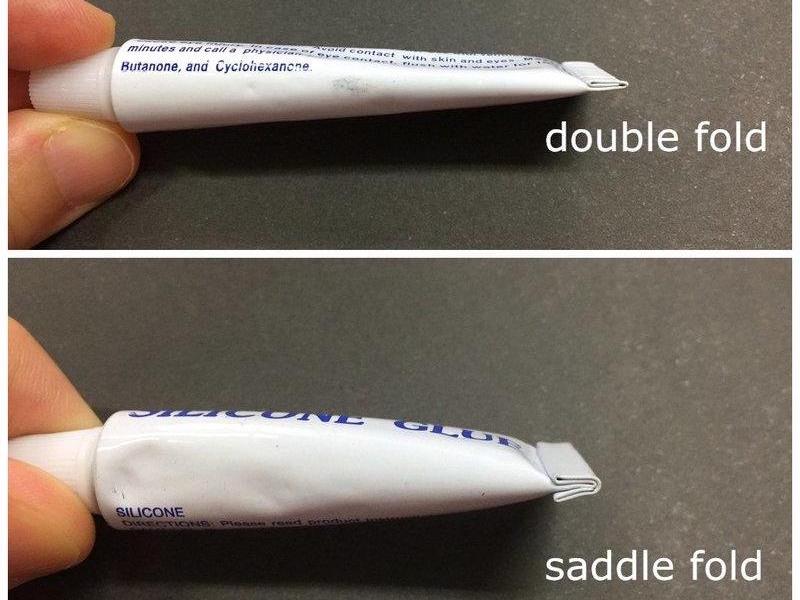

Once the adhesive has been filled into tubes, the tube end will be folded and crimped, favorably by automatic sealing machine. This is the final procedure of packaging. Double fold, as seen in the image, is the most common type of folding. For sensitive adhesive, saddle fold is highly recommended as it provides better tightness. (Reference: The Art of Sealing and Folding for Metal Tube Packaging)

Xin Yi offers empty aluminum collapsible tubes for adhesive products. Special treatments are added to tubes that require higher level of air-tightness. For more information on aluminum glue tube supply, please contact Xin Yi today: sales@tubenaire.net

Read More: Choosing the Right Suppliers for Empty Glue Tubes