Selecting the right supplier for empty glue tubes to package adhesives and sealants is a critical decision that directly impacts the quality, functionality, and success of your products. Adhesives and sealants require reliable packaging that ensures longevity, prevents leakage, and maintains their efficacy. Let’s look at the key points to evaluate supplier and to make an informed choice:

1. Define Your Needs:

Begin by outlining your specific requirements, such as the quantity of tubes needed, tube size, barrier properties, and any special features. Clear communication about your needs will enable potential suppliers to understand your expectations.

2. Research and Shortlist:

Conduct thorough research to identify potential suppliers who specialize in producing empty glue tubes. Look for suppliers with a proven track record and a reputation for delivering high-quality products.

3. Experience and Expertise:

Choose suppliers with experience in producing packaging solutions for adhesives and sealants. Their expertise in this specific field will ensure that they understand the unique requirements and challenges associated with these materials.

4. Quality Standards:

Ensure that the supplier adheres to strict quality control processes. Look for certifications, which demonstrate their commitment to producing safe and reliable packaging materials suitable for adhesives and sealants.

5. Material Sourcing and Compatibility:

Inquire about the origin and quality of the raw materials used for the tubes. The materials must be compatible with adhesives and sealants to prevent reactions that could compromise the integrity of the products.

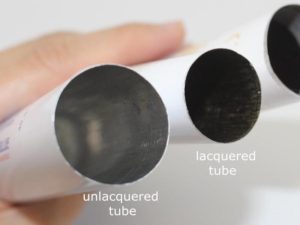

6. Barrier Properties:

Adhesives and sealants require packaging with effective barrier properties to prevent leakage, drying, and contamination. Discuss with potential suppliers how their empty glue tubes offer the required barrier against air, moisture, and light.

7. Customization and Printing:

Discuss the customization options available for your adhesive tubes. Can the supplier accommodate specific printing requirements, branding, and labeling that align with your product’s identity?

8. Samples and Communication:

Request samples of their empty glue tubes. Assess the quality, design, barrier properties, and overall functionality of the tubes to ensure they meet your standards. Evaluate the supplier’s communication skills and responsiveness. Effective communication is crucial to avoid misunderstandings and ensure that your needs are met throughout the production process.

Selecting a reputable supplier for empty glue tubes to package adhesives and sealants requires careful consideration of their expertise, quality standards, and customization options. Investing in the right packaging partner ensures that your products remain protected, reliable, and in peak condition for your customers.

Guangzhou Xinyi Enterprise Ltd produces aluminum collapsible tubes for adhesives and sealants, such as silicone glue, epoxy adhesive, neoprene, super glue and rubber cement. Sizes range from 3 ml to 90 ml. Please contact us for free samples and pricing information: sales@tubenaire.net

For Your Information:

XINYI Factory Production (Photo Gallery)