In the world of product packaging, empty aluminum squeeze tubes have emerged as a versatile and durable option. These packaging tubes are perfect for a wide range of products, from cosmetics to pharmaceuticals and beyond. One crucial aspect of creating a visually appealing product is printing on these aluminum tubes. Now let’s explore the process of printing on aluminum collapsible tubes, how it differs from paper printing, the distinctions between offset and screen printing, and how to prepare your artwork for this unique medium.

Printing on Aluminum Squeeze Tubes

First things first, printing on empty aluminum squeeze tubes is a specialized process that varies significantly from traditional paper printing. While paper is flat and readily accepts ink, aluminum packaging tubes are cylindrical and made of metal, which presents its own set of challenges.

One of the key differences is that aluminum is not as porous as paper, so inks don’t absorb in the same way. Instead, special inks and printing techniques are required to ensure that the artwork adheres to the tube’s surface without smudging or fading.

Offset Printing vs. Screen Printing

When it comes to printing on empty aluminum squeeze tubes, two primary methods are commonly used: offset printing and screen printing.

1. Offset Printing: This method is akin to traditional lithographic printing, where the ink is transferred from a plate to a rubber blanket before being applied to the tube’s surface. Offset printing is ideal for intricate designs with a wide range of colors and gradients, as it can reproduce fine details accurately.

2. Screen Printing: Also known as silk screen printing, this technique involves pressing ink through a fine mesh screen onto the tube. Screen printing is fantastic for bold, vibrant designs and is often used for logos and text. It’s a cost-effective choice for large runs of tubes with the same design.

Preparing Artwork for Aluminum Collapsible Tubes

Now, let’s discuss how to prepare your artwork for printing on these unique containers:

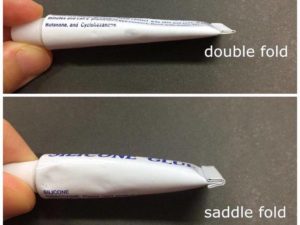

1. Size Matters: Determine the size and shape of empty aluminum squeeze tubes. It’s crucial to create artwork that fits seamlessly, taking into account any folds or seams that may interrupt the design.

2. Resolution and Color Mode: Ensure your artwork is high-resolution (at least 300 dpi) and use the Pantone color mode to match the ink used in the printing process.

3. Vector Graphics: Whenever possible, use vector graphics for your design. They are scalable without loss of quality, ensuring your artwork looks crisp no matter the size.

4. Special Inks: Keep in mind that metallic inks and spot colors might be necessary to achieve certain visual effects. Work closely with your printer to select the right inks for your design.

5. Mockups and Proofs: Always request mockups or proofs from your printer to see how your artwork will appear on the final product. This step allows for adjustments before mass production begins.

Although printing on empty aluminum squeeze tubes may differ significantly from paper printing, you can create eye-catching and durable packaging for your products with the right knowledge and preparation. Whether you opt for offset or screen printing, understanding the nuances of each method will help you make the best choice for your specific needs.

Guangzhou Xinyi Enterprise Ltd is an aluminum collapsible tube supplier based in China. We offer offset tube printing that makes your products stand out with stunning aluminum collapsible tube designs! Please contact us for free samples and pricing: sales@tubenaire.net