When it comes to packaging adhesive glue in aluminum packaging tube, one of the most essential concerns is whether adhesive glue can be stored in these tubes properly. In particular, we expect the glue to remain intact in tubes even after a long period of time, not to dry out fast and not to leak out of tube. Now, how do we make sure these tubes can be sealed up tight?

As one can imagine, air, moisture, oxidants and other contaminants come from external environment and might cause adhesive glue to dry out soon. For example, adhesives as sensitive as silicone sealant and epoxy adhesive always require extra tightness of packaging.

An experienced tube supplier would know how to reach the desired air-tightness. There are mainly two aspects to look at. First, the quality of aluminum slugs from which tubes are extruded is to be evaluated. High quality aluminum slugs have optimal density so that the aluminum tube wall (after extrusion) is sturdy enough to effectively isolate contents from external environment.

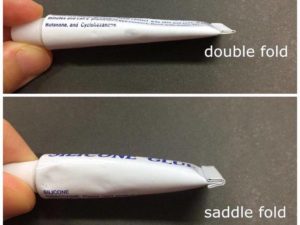

Second, an experienced tube supplier would consider having tubes “latex-lined”. Latex is a soft substance with high elasticity. It is a non-toxic material and would not have chemical interactions with the contents. Latex lining involves applying a band of latex to the inner wall of tubes near the open end. This small band helps to clog the interspace as tubes are crimped so that the contents would be securely isolated from external environment. It prevents content leakage and also prevents moisture and contaminants from penetrating into tubes.

Although latex lining is a common technique in tube making process, not all paste products require latex-lined tubes for packaging. It depends on the degree to which the contents are susceptible to air, moisture and other contaminants from outside the tubes. Some adhesives dry fast; some react easily to moisture or air; and still others contain tiny molecules and easily leak out of tubes. These are the contents to be kept strictly airtight.

When latex lining is considered necessary, it would be applied to tube as the last procedure of tube making. The width of latex band is adjustable in order to reach the best airtight results. Can one imagine a small white band can make such a difference to product quality?

Guangzhou Xin Yi Enterprise Ltd. is an aluminum tube manufacturer specialized in tubes from 8mm to 32mm diameter. Xin Yi is experienced in tube making for packaging adhesive glue as well as cosmetic products. The quality of aluminum packaging tube is essential. Please contact Xin Yi for further information on tube making and pricing: sales@tubenaire.net