In the world of packaging, aluminum collapsible tubes stand as stalwart guardians of our everyday essentials. From our favorite toothpaste to essential cosmetics and life-saving ointments, these versatile containers protect and dispense a wide range of products efficiently. Yet, behind the scenes of this unassuming packaging lies a crucial ingredient – aluminum slugs. Here let’s look at the fascinating world of aluminum slugs, exploring how they are made and why their quality is pivotal to the excellence of extruded aluminum tubes.

Before we venture into the intricacies of aluminum slugs, let’s take a moment to appreciate the significance of aluminum collapsible tubes. These cylindrical wonders have become an integral part of our daily lives, offering numerous benefits:

1. Protection: Aluminum collapsible tubes provide an airtight and light-resistant environment for the products they contain, ensuring extended shelf life and product freshness.

2. Convenience: Their easy-to-squeeze design allows precise dispensing, minimizing product waste and promoting user convenience.

3. Versatility: Collapsible tubes are used for a wide range of products, from cosmetics and personal care items to pharmaceuticals and adhesives, making them a versatile choice for manufacturers.

How Aluminum Slugs become Collapsible Tubes

The production of aluminum collapsible tubes involves a fascinating process that begins with the creation of aluminum slugs. Here’s a step-by-step breakdown:

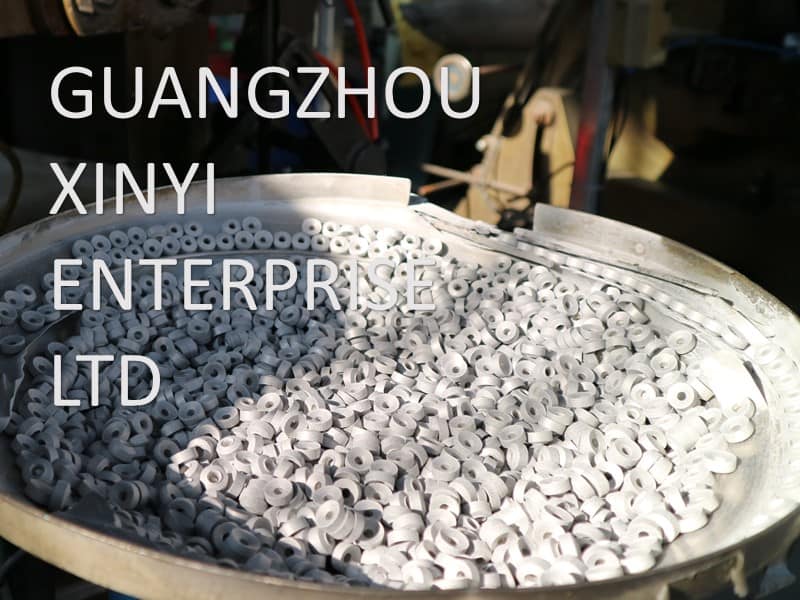

1. Aluminum Slug Creation: Aluminum slugs are produced from high-quality aluminum ingots, which are melted and then cast into cylindrical shapes. These cylindrical blocks are then cut into smaller pieces, known as aluminum slugs. The size and weight of these slugs vary depending on the specific requirements of the collapsible tube being produced.

2. Slug Extrusion: These aluminum slugs are then extruded to form the body of the collapsible tube. During this process, the slug is forced through a die to create a seamless, cylindrical tube shape. This extrusion process is what gives collapsible tubes their distinctive form.

3. Tube Formation: The extruded aluminum tubes are further processed, such as being coated with a protective layer on the inside to prevent chemical reactions between the product and the aluminum.

The Quality of Aluminum Slugs Matters

Now that we understand how extruded aluminum tubes are created, let’s explore why the quality of aluminum slugs is paramount to the quality of the end product:

1. Consistency: High-quality aluminum slugs ensure uniformity in the thickness and texture of the collapsible tube, which is vital for aesthetic appeal and functionality.

2. Durability: Quality slugs lead to more robust tubes that can withstand external pressures and resist deformation during transportation and use.

3. Barrier Properties: The purity and quality of aluminum slugs play a significant role in maintaining the integrity of the product inside. Poor-quality slugs may result in unwanted reactions between the product and the aluminum, affecting the product’s quality and shelf life.

4. Aesthetics: Superior slugs yield collapsible tubes with a smooth and even surface finish, enhancing the visual appeal of the packaging.

Aluminum slugs may not always be in the spotlight, but they are undoubtedly the unsung heroes of collapsible tube packaging. As consumers, we appreciate the convenience and functionality of these tubes in our daily lives, but it’s equally important to acknowledge the craftsmanship and precision involved in creating them.

So, the next time you pick up your favorite toothpaste or skincare product, take a moment to imagine how aluminum slugs become extruded aluminum tubes and appreciate the slug that made it all possible. Behind every squeeze of that collapsible tube lies a world of quality craftsmanship and dedication to ensure that your product remains safe, effective, and stylish.